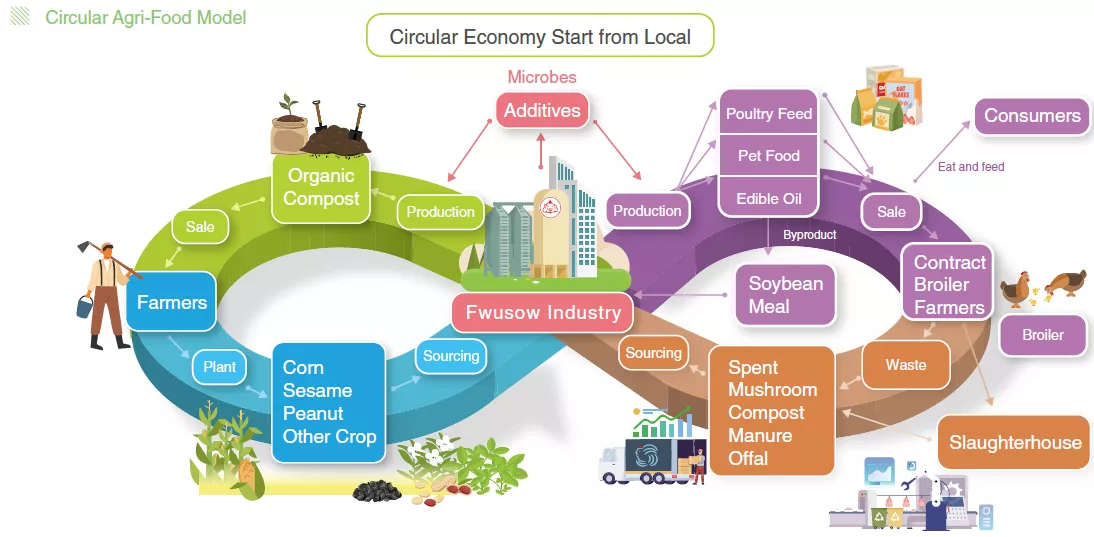

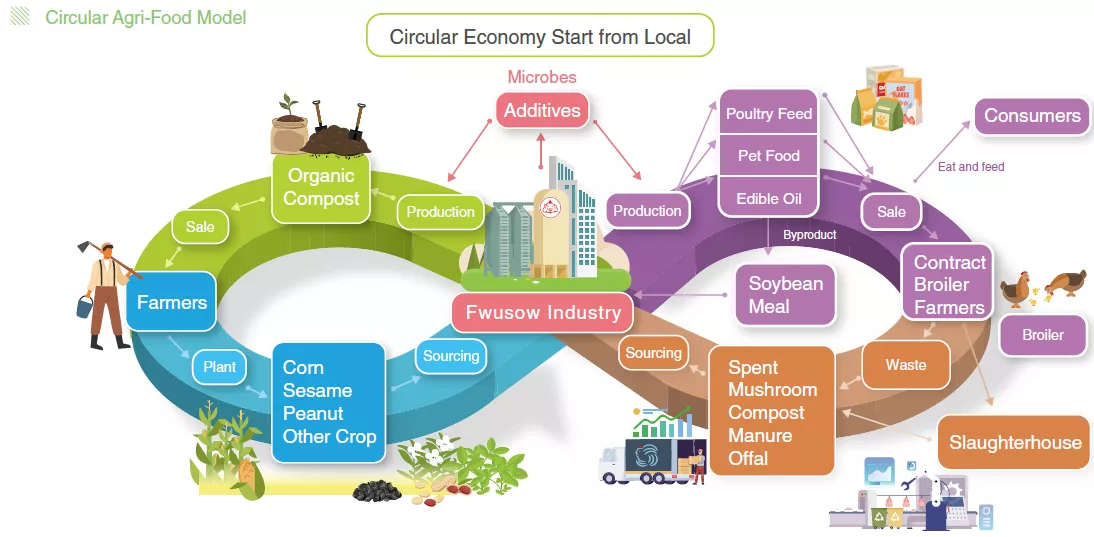

Circular Agri-Food Economy Applications

To support the government's advocacy of organic composting and eco-friendly farming policies, we provide contract farmers with professional knowledge and technical assistance to improve their farming practices along with the use of biopesticides and organic composting techniques to enhance crop growth. This approach aims to increase the efficiency of resource utilization and establish a circular agricultural economy. Furthermore, we purchase the crops grown by farmers for our production, thereby creating a sustainable circular agri-food system.

In 2024, we have recycled 15,190.9 tons of mushroom compost, 8,854.6 tons of poultry manure, 1,770.6 tons of bleaching clay, and 1,601.2 tons of food sludge. And produce 21,801.2 tons organic compost fertilizer for agricultural cultivation.

Read More

Read More

Note: Obtained the waste treatment permit for bleaching clay and food sludge in 2021

In 2024, we have recycled 15,190.9 tons of mushroom compost, 8,854.6 tons of poultry manure, 1,770.6 tons of bleaching clay, and 1,601.2 tons of food sludge. And produce 21,801.2 tons organic compost fertilizer for agricultural cultivation.

Read More

Read More| Recyclable Waste Material Collection & Organic Fertilizer Chart Unit: tons |

|||||

| Year\Item | Recyclable Waste Material Collection Quantity | Organic Compost Fertilizer | |||

| Spent Mushroom Compost & Wood Sawdust | Poultry Manure | Bleaching Clay | Food Sludge | ||

| 2022 | 2,622.8 | 1,841.1 | 1,479.7 | 1,168.8 | 10,407.5 |

| 2023 | 3,204.1 | 3,226.6 | 1,296.0 | 989.8 | 17,207.4 |

| 2024 | 15,190.9 | 8,854.6 | 1,770.6 | 1,601.2 | 21,801.2 |

Through carbon labels, they provide insight into carbon and other greenhouse gas emissions from the production process; thus, we can modify the process flow, packing material and transportation to reduce carbon emissions.

- We continue to hold Carbon-Footprint labels for 22 products in sesame oil, dried bonito flakes, and pet food in 2024.

- We regularly update the contents in the three product category rules (PCR).

- In 2025, we expanded our carbon footprint label verification to include 5 of the Cerear grain series of products.

Sesame Oil, Dried Bonito Flakes, and Pet Food Product Carbon Footprint Label Certificates

Sale of Carbon Footprint Label Products Unit: label count

Read More

Read More| Carbon Footprint Label Products \Year |

2022 | 2023 | 2024 |

| Fwusow Sesame Oil (217ml、543ml) |

122,239 | 104,928 | 128,316 |

| Fwusow Dried Bonito Flakes (5g、10g、120g、300g、600g) |

270,065 | 296,612 | 246,832 |

| Greens Dog Food Series (15 products) |

576,729 | 386,487 | 394,874 |

Note: The quantity is calculated based on the actual use of the Ministry of Environment carbon label

- We maintain sales of 2 low environmental impact products with Green Mark certification in 2024, totaling 2,603 tons.

- We reduce 1 product certification in comparison of 2023, due to adjustment in product sale strategies.

Read More

Read More| Product Name | Green Mark Certication |

| Chia Fa Organic Fertilizer | 10294 |

| Natural Organic Fertilizer | 10296 |

Organic Farming Products

- In 2024, we maintained certification for 14 organic material products, amounting to 14,536 tons, increased by 35.62% compared to 10,718 tons in 2023. The increase is attributed to continuously rising of demands from organic compost use. And we used intelligent agriculture technology and microbial technology that promote crop yield and efficiency in harvest.

- In 2024, 1 violation occurred: the mistake of fertilizer label mark, resulting in a fine of NT$50,000. We responded to downgrade the content of organic materials, and reapplied for the certification.

Read More

Read More| Product Name | Organic Farming Number |

| Organic culture fertilizer 426 | 100001 |

| Organic culture fertilizer 522 | 100014 |

| Natural organic fertilizer | 101017 |

| Organic culture fertilizer 532 | 101018 |

| Fwusow organic fertilizer 1 | 107018 |

| Fwusow Neem Oil | 107032 |

| Fwusow Compost 3 | 109013 |

| Fwusow Tianzhong 1 | 109019 |

| Fwusow Sesame Meal | 109021 |

| Dr. Fertilizer water soluble fertilizer | 111003 |

| Fwusow Organic Fertilizer 355 | 111009 |

| Fwusow Biolife #1 | 111010 |

| Fwusow Compost 7 | 113022 |

| Fwusow Compost 6 | 113024 |

Animal Welfare & Animal-Friendly Feeding

Our ecological farm in Zhongliao Township, Nantou County offers a comfortable, spacious breeding environment and the modernized climate-smart farm and allows the animals to have access to plenty of sunshine, outdoor surroundings, and the opportunity to express their natural behaviors to ensure animal welfare.

To minimize the effect on growth of animals from the climate changes, our farms are enclosed with smart sensors. We focus not only on the natural grazing environment but also on the biological preventive measures in making sure to reduce contamination sources.

Read More

Read More| Breeding Environment | Layer Chicken Production System |

Cage Free Layer Hen |

Pasture Chicken (Free Range) |

|

| Breeding density (m2/chick) |

Floor Feeding, Cage free - indoor |

0.08 | 0.125 | 0.125 |

| Cage free - outdoor |

0.16 | 1 | 0.5 | |

| Other | 7 layer chicken per nesting box |

6 cage free layer hens per nesting box | Cage free and free to roam after 6 weeks | |

Note: Council of Agriculture "Layer Hen Friendly Production System Definition and Guidelines"

Read More

Read More| Type | Poultry | Livestock | ||||

| Layer Hen | Pig | |||||

| Year | 2022 | 2023 | 2024 | 2022 | 2023 | 2024 |

| Count/ Head |

20,200 | 17,400 | 12,800 | 2,814 | 1,860 | 251 |

| % animal welfare with cage free |

20.61 | 27.7 | 25.6 | 7.3 | 7.3 | 1.9 |

Note:

- Pig breeding practices natural pasture farming

- We have fed for 500 colored broilers in 2023, but suspended since 2024.